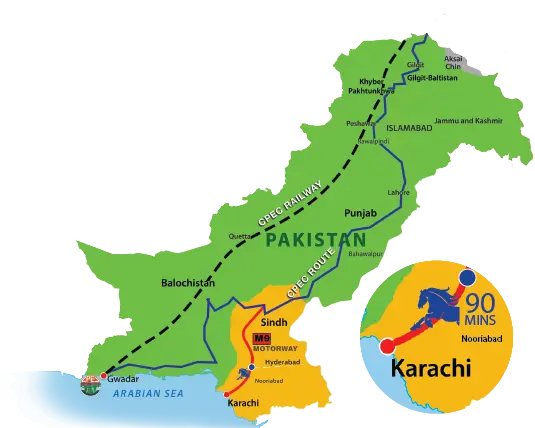

OVERVIEW

Pakistan's leading producer of premium yarn located in S.I.T.E. Nooriabad

ENHANCED EFFICIENCIES

SUSTAINABLE CONSISTENCIES

ENDURING TECHNOLOGY

MAXIMIZING VALUE

SPINNING SERVICES

QUALITY ASSURANCE

TOLL MANUFACTURING

RELIABLE DELIVERIES

PRODUCTION PROCESS

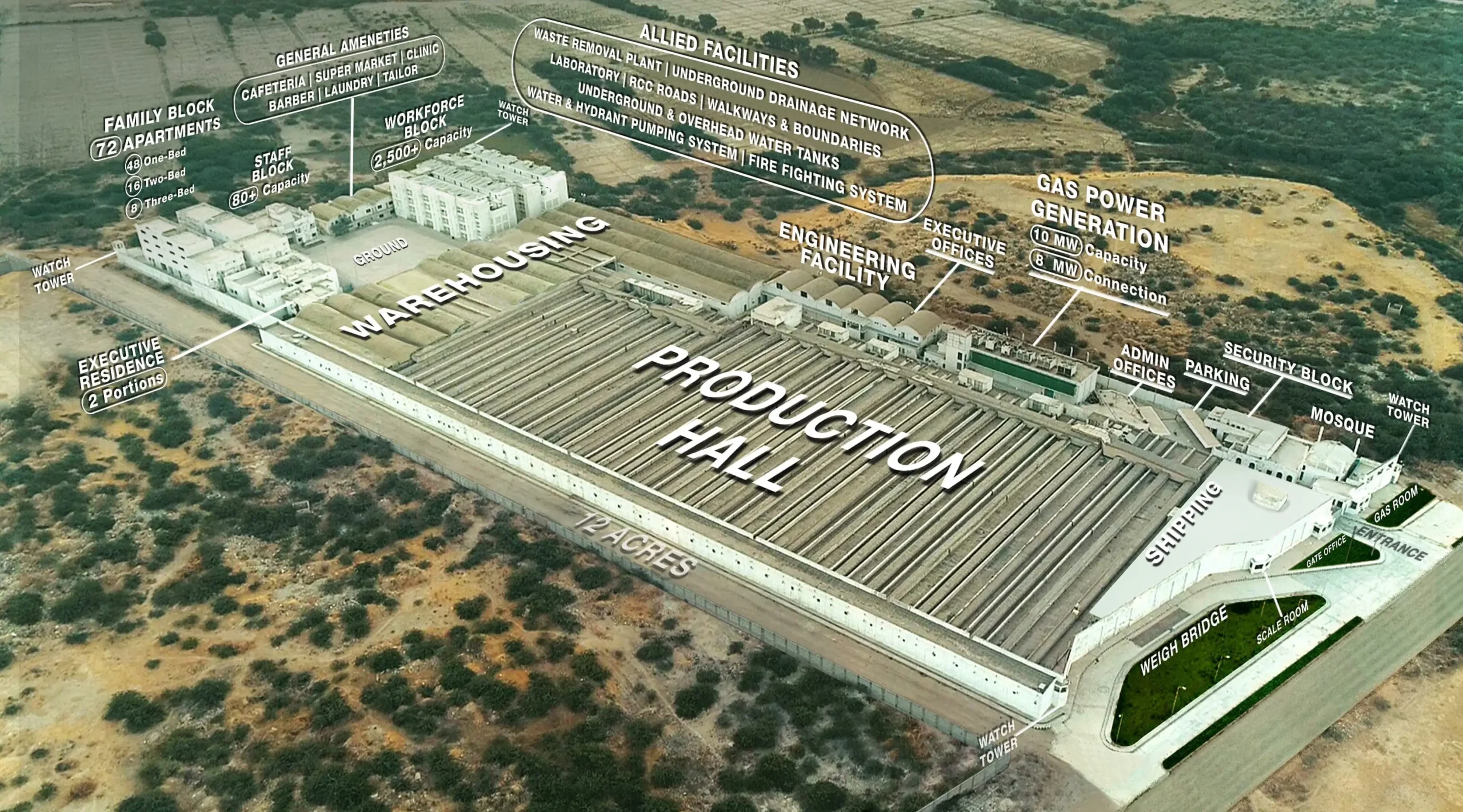

INFRASTRUCTURE

Aerial View

Warehousing

power generation

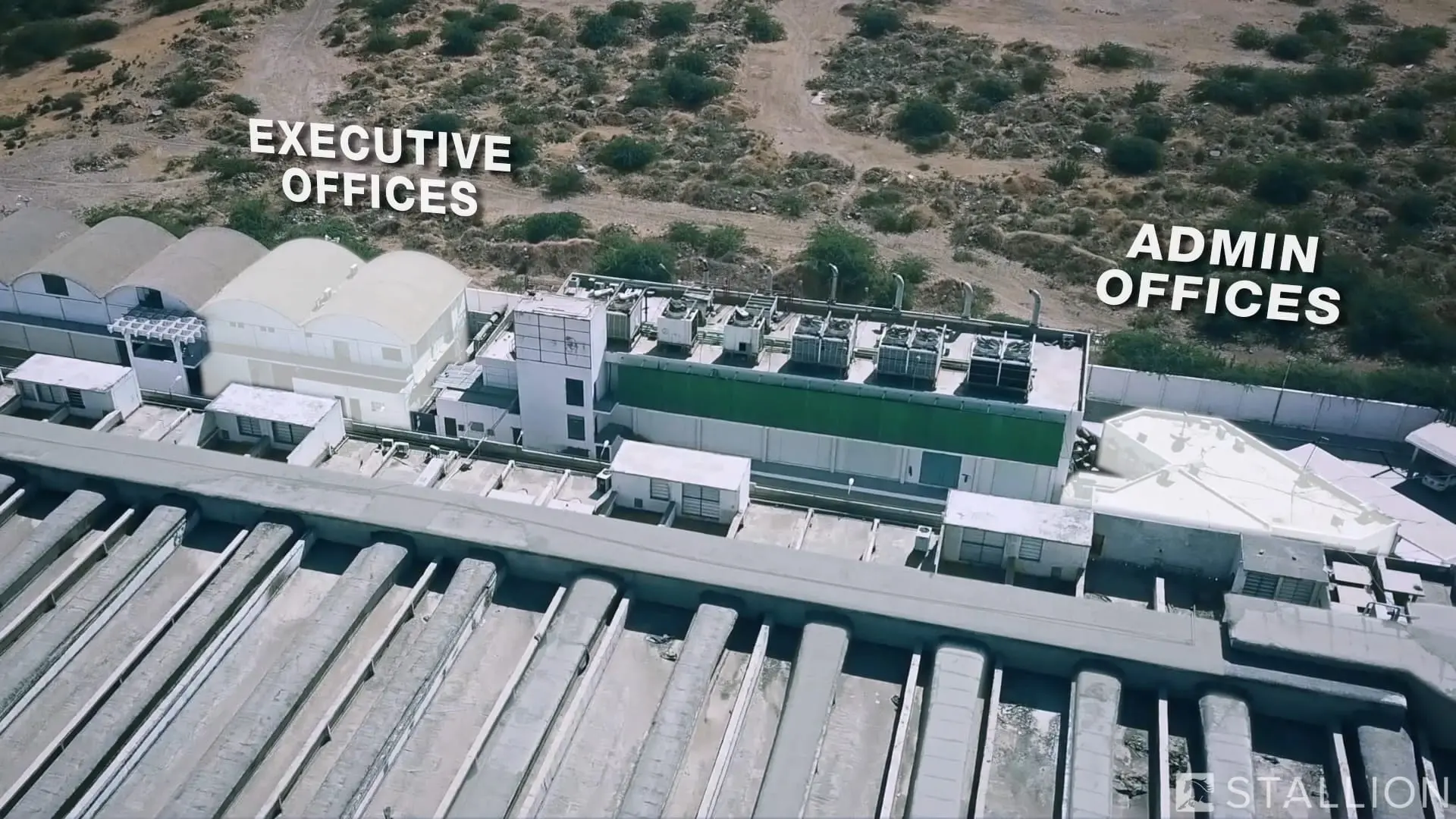

Engineering Facility

Office block

Allied Facilities

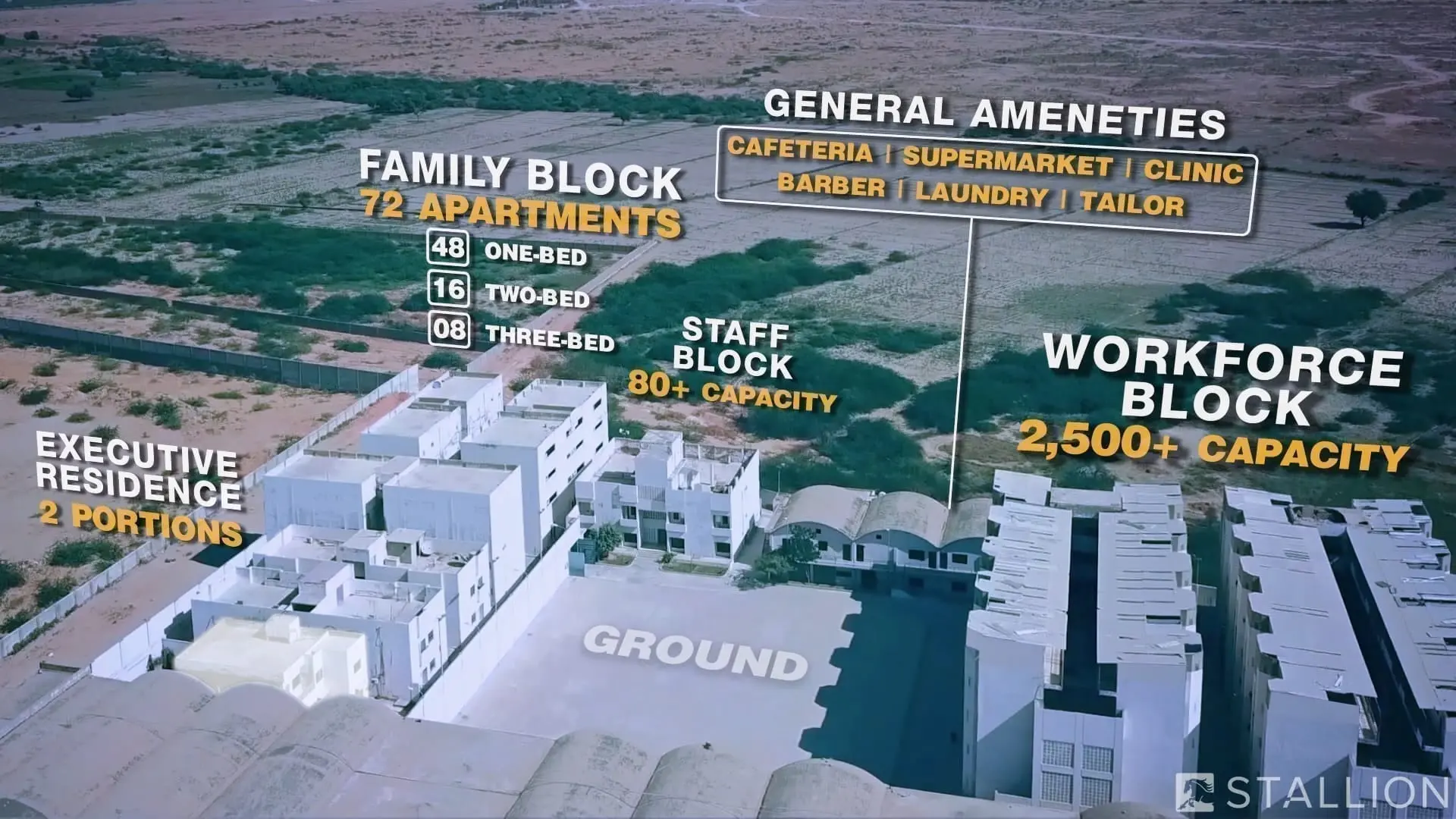

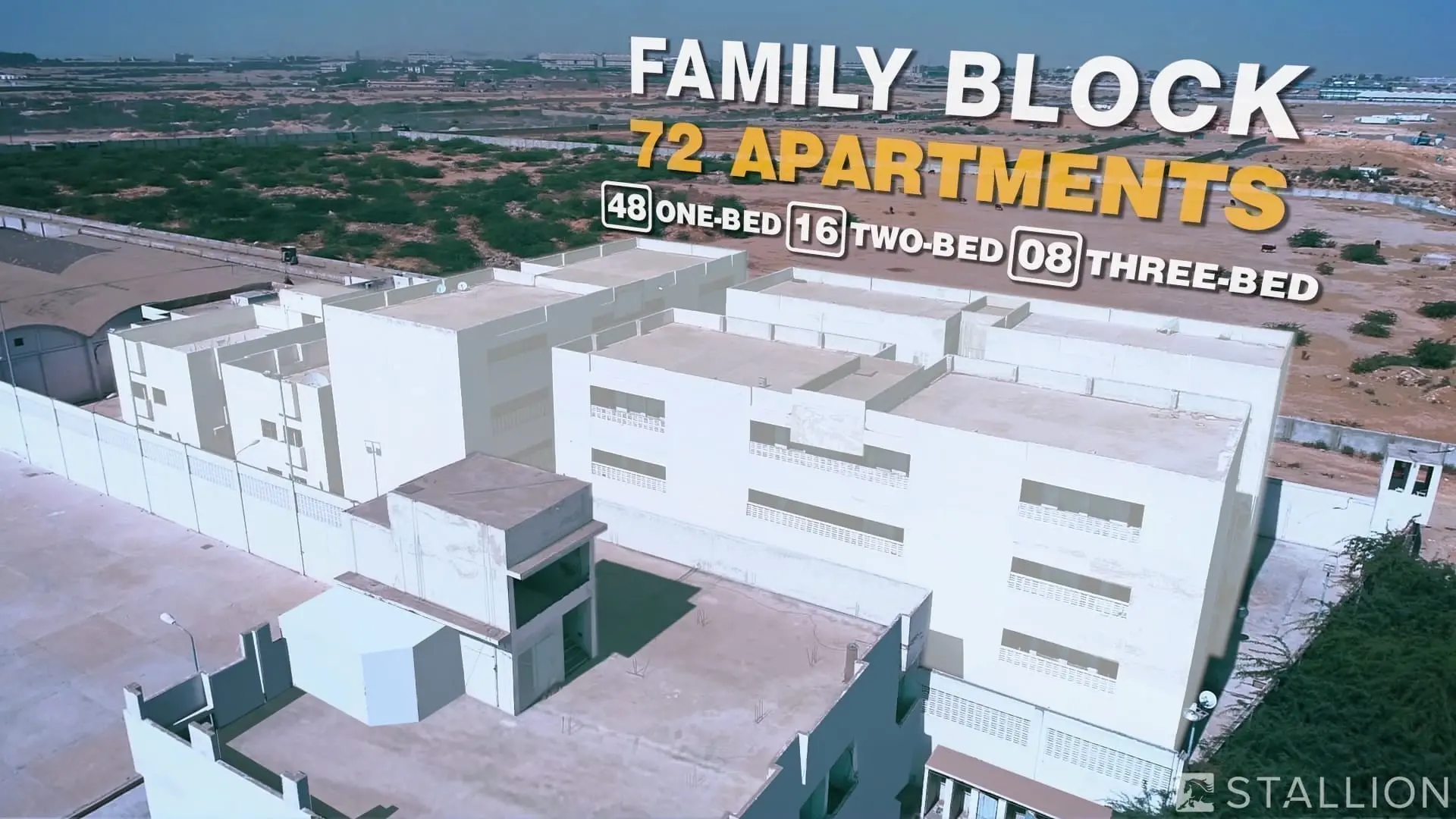

Residential Block

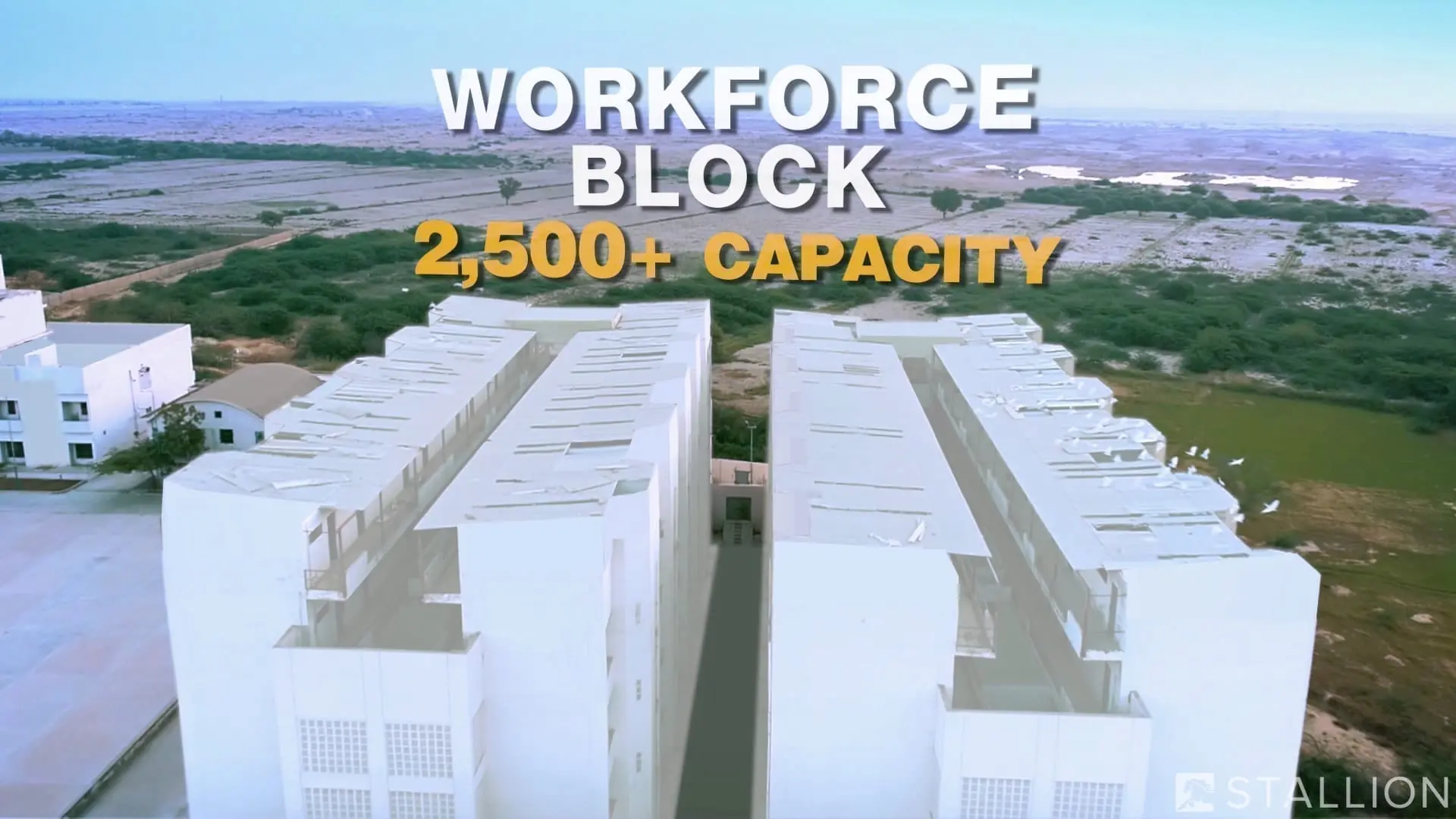

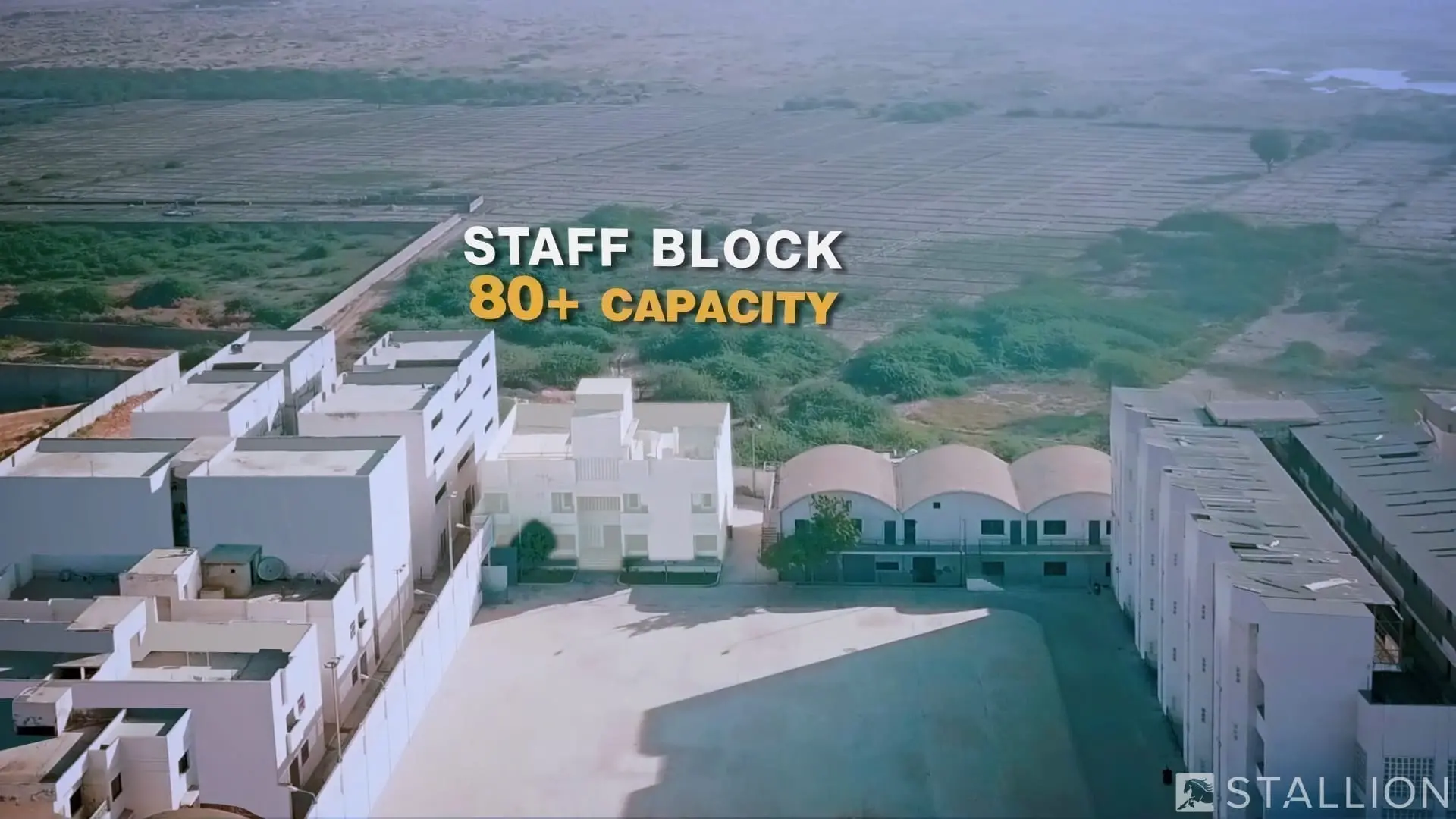

Workforce Block

Family Block

Staff Block

General Amenities